Substrates: Different Types And How To Use Them

MARCH 31, 2023| kaylarCategories

UncategorizedIn the large-format print world, we use a variety of substrates with different finishes to create the specific signage look our customers seek. For instance, if you’re looking for temporary roadside advertisements, we’ll probably suggest coroplast as opposed to acm due to coro’s temporary nature and low cost. Sometimes, we use a combination of substrates to achieve the desired display. Brushed aluminum lettering surrounded by custom acrylic displays may be just the combination your Partner’s Wall needs.

With your goals in mind, we recommend the best type of substrate(s) for your project. Some materials are more temporary in nature, while others create a look of professionalism. Still other can be cut or designed in a way to create displays unique to your business. In order to help you understand more about the materials we’re talking about, we’ve compiled short descriptions for our most popular substrates. Here, we will discuss the various types of substrates, their unique specs and how to best utilize each material.

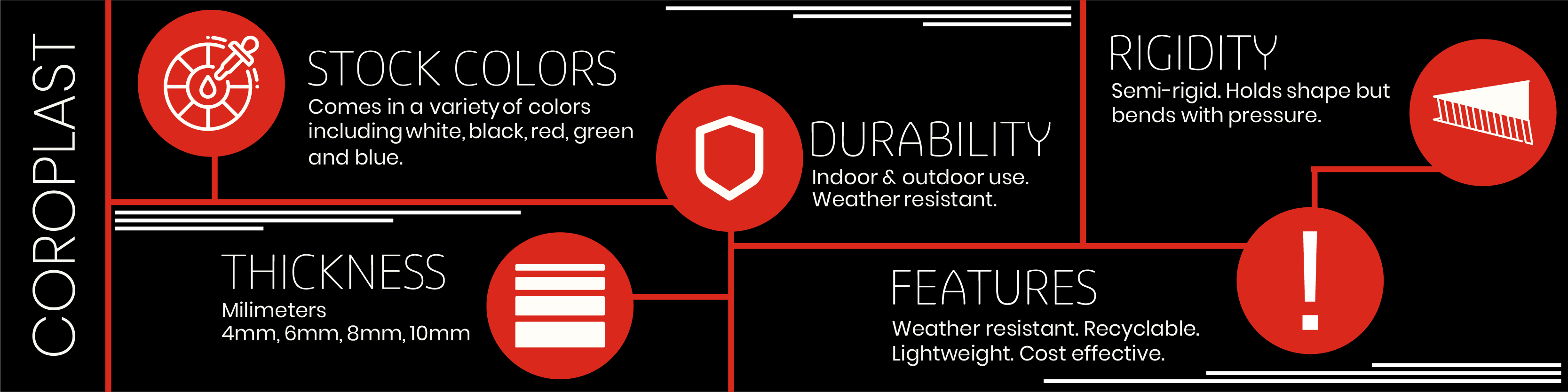

Substrate: Coroplast

Substrate: Coroplast

Coroplast is a type of corrugated plastic often used for temporary and outdoor sign applications. The corrugated substrate features a liner made of a folded material sandwiched between two flat layers of plastic. The inner layer’s ridges and furrows help to strengthen and reinforce the plastic faces. People often call coroplast “plastic cardboard” because of its physical similarity to cardboard.

Types of Coroplast Signage

Because of its weatherability, many businesses use coro signage for roadside advertisement, commonly known as yard signs. Coroplast holds up well under most weather conditions and comes at a relatively inexpensive price compared to other substrates.

Coroplast point-of-purchase (POP) displays come in all shapes and sizes. You typically see this type of displays at check-out counters, near shop entrances or at the end of grocery aisles. POP fabricators first print your custom marketing on the material, then die-cut the coro using a cutting template. Finally, the fabricator connects the pieces to form your custom display.

Coro is also great for smaller hand-held signage seen at photo booths or tradeshow. The lightweight material is easy to hold, store and transport, though it will bend if someone bends or steps on it. Since the material is on the less expensive end of substrates, you shouldn’t have a problem ordering hand-helds for each event.

Substrate: Ultraboard

Substrate: Ultraboard

Ultraboard goes by many names — foamcore, gatorboard, foam board, paper-faced foam — and chances are, you’ve seen it before. “Ultraboard” is a brand name turned household word that we use to refer to our foamcore substrates. As it happens, Ultraboard is also the brand we stock.

To create ultraboard, manufacturers sandwich a polystyrene center between two sheets of thick, matte paper. The core’s plastic contains more than 95% air, making the material extremely lightweight and portable. But because it’s made of foam, it’s also relatively easy to damage. In most sizes and thicknesses, foamcore keeps its rigidity, though you may want to use wall hardware and easels to display the prints.

Types of Ultraboard Signage

Ultraboard is great for any signage that doesn’t involve regular handling or exposure to the elements. In many cases, companies use ultraboard for temporary event or meeting displays since the substrate is easy to transport and is relatively inexpensive. As the step up from coroplast, ultraboard does not sport the “ridges” look that coro does, making the material preferable for professional settings.

Many businesses also use ultraboard prints as office wall hangings. We’re able to print any custom design on vinyl, then adhere that vinyl to the ultraboard. You can hang these prints just about anywhere using command strips. Some offices choose to spruce up the ultraboard look by using standoffs.

Substrate: Aluminum Composite

Substrate: Aluminum Composite

ACM (Aluminum Composite) is a rigid metal sheet made by two sheets of pre-finished aluminum sandwiching a polyethylene core. Although we typically think of metal as heavy, ACM is lighter and more cost-effective than a solid aluminum sheet made in the same gauge. ACM lays flatter than traditional aluminum sheets and doesn’t suffer from the rippling effects of other metallic substrates.

Types of ACM Signage

Large format printers generally use ACM for exterior signs because the material is durable and lightweight, but you can also find ACM used in indoor projects as well. Because of the material’s rigidity, sign makers can route or cut it to whatever shape needed.

Outdoor signage includes a multitude of different signs: banjo displays (a more professional looking yard signs), post and arm signs (typically used for real estate), parking lot markers, outdoor directional signage and exterior building signs. The rigid material can be cut down to any size that fits your purpose, and we can custom print your business’ advertising design.

Brushed aluminum is a sister product to ACM. Instead of two pieces of aluminum on a core, brushed aluminum is a single sheet of thin, anodized aluminum. Depending on how you want to use the material, it’ll come as a sheet or applied to other substrates to create dimension. Brushed aluminum dimensional lettering has been a popular interior sign product for many businesses.

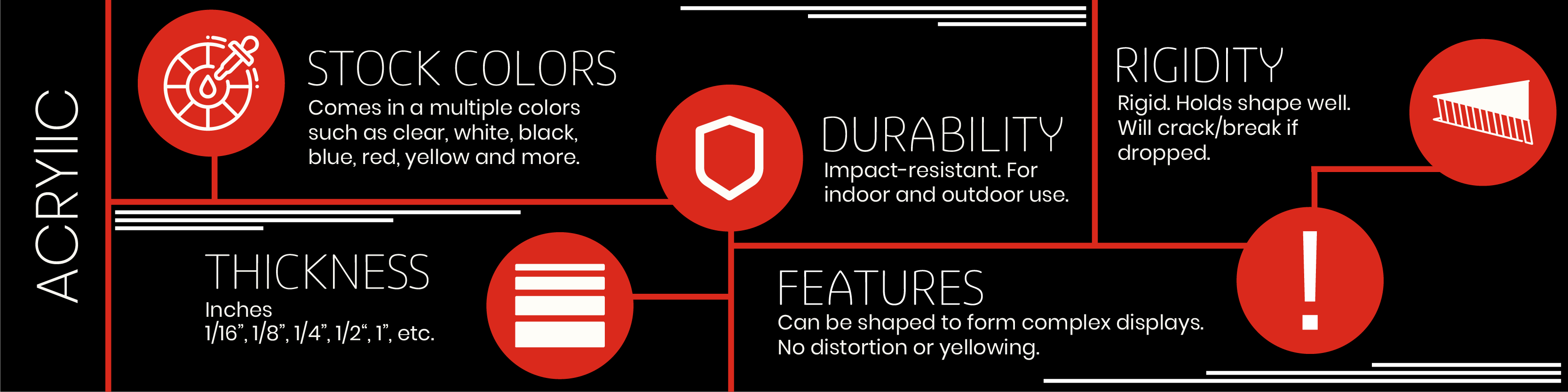

Substrate: Acrylic

Substrate: Acrylic

Acrylic, also referred to as plexi or lexan, is a transparent plastic material. Its glass-like qualities make it a popular substrate for aesthetic wall displays and translucent signage. Appearance-wise, plexi comes in varying translucencies and colors, and thicknesses range from inches to a fraction of an inch. Additionally, acrylic can be cut in different shapes and sizes, making it very easy to craft a creative display.

Although plexi mimics glass in transparency and brilliance, the substrate weighs half the weight of glass and is much more impact-resistant. It also cuts, bends, and polishes well to get the finished result you love most. Plexi displays are popular for both indoor and outdoor applications due to the material’s crisp look and natural durability.

Types of Acrylic Signage

Acrylic goes well with backlights, spotlights, 3D lettering and many other additional visual accessories. Standoff wall displays are among one of the most popular interior acrylic uses. The standoffs allow your plexi display to “float” on your wall, giving the display extra dimension.

Another popular use of acrylic involves cutting the material to create custom cut shapes and letters for dimensional lettering displays. Acrylic comes in many stock colors, but it can also be painted to match your specific color scheme.

Many businesses choose to use acrylic for their directional and ada signage. The acrylic can be back-painted your custom color, then be front-lettered with white text and raised braille letters. Or, you can choose to use a stock color acrylic and have the needed text cut from vinyl for non-braille signage.

Why Is Knowing Your Substrates Important?

For the average signage customer, understanding your substrates isn’t crucial. However, knowing the differences in the materials helps you better understand the product you’re ordering and how to expect it to look. This knowledge also helps you make informed decisions as you consider your signage needs.