Are you looking for unique signage with a custom-cut design? If so, contour-cut signage from SpeedPro is the perfect solution.

At SpeedPro, we can create virtually any shape or pattern with our state-of-the-art contour cutting technology. Your project will be customized down to every last detail, as we offer contour cutting for many different substrates and designs. The final product is limited by your imagination alone — we’ll gladly tackle any request.

With a nationwide network of locations, SpeedPro provides quality products with personalized customer service. Learn more below about our capabilities regarding custom contour-cut signage and the benefits these types of signs and decals can provide for your organization.

What Is Contour-Cut Signage?

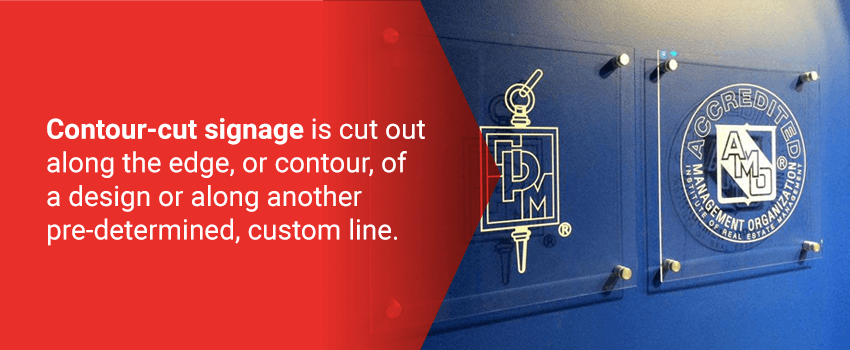

Contour-cut signage is cut out along the edge, or contour, of a design or along another predetermined, custom line. Typically, contour-cut signage has little to no border, and the final product is just the shape of your logo, company name, custom shape or whatever other design you chose. The possible configurations for contour-cut signs are virtually limitless.

Contour cutting is like cutting a picture out of a magazine with scissors, except you’re using a highly precise cutting machine and software program and cutting the shape out from high-quality signage material. The machine used for contour cutting is called a digital cutter or router. First, you’ll design your sign, then print it out and use this machine to cut it out.

You can use the technique of contour cutting on many different materials to create various kinds of signs and decals. It’s one of the most customizable, precise and efficient methods used for creating signage, and it’s ideal if you want a borderless sign or unique shape that will help your sign stand out and make a bold statement.

How Is It Achieved?

The process of making a contour-cut sign involves three main steps — design, printing and cutting.

Design

In the design step, you start creating your design artwork as you would when using any other printing and cutting method. You will also, however, need to add in registration marks. These marks, also called contour-cut marks, help the cutting machine to align itself correctly with the design. The cutting device references these marks when plotting the cut path to make sure it’s in the right place.

These registration marks may be located at the four corners of the outer border of the print area. These types of marks are typically unique to the cutter being used. They may look like a target, circle or another shape, but different brands and models of cutters recognize different marks. These registration marks are typically printed in black ink.

A design may also have multiple registration dots positioned around the area that will be cut out. These marks are black dots that are typically between 1/8″ and 1/4″ in size. They should be placed in even increments around the edge of the design to help the cutter stay aligned.

A design file for contour cutting may also require a cutting line. Sometimes, a machine can detect the contrast between a light background and the dark print, but you may also need to define the line along which to cut, especially if you want to cut a shape that doesn’t mirror the design’s outline exactly.

This cut path will be continuous, ending at the same point where it began. It can follow any shape, but it’s best to avoid exceptionally thin sections, as these sections can be brittle once cut. For safety reasons, it may also be best to avoid sharp points depending on the material you’re using. The path may run just inside the edge of the design to allow for a small safety margin. This cut path will not be printed. Instead, the cutting machine will use the information provided for determining where it will cut to create the sign.

It doesn’t matter what the line looks like — just that the machine can recognize it so that it knows where to cut the material being used. Often, you need two files when contour cutting a sign. One file will contain the artwork and registrations dots or marks, while the other contains the cutting path. The cutting file may be overlayed on the artwork file, showing where the cutting path lies on the design.

Printing

Once you have the design files created, saved and ready to go, the next step is printing. You can print the design onto the material you’ll be using like you would with any other type of signage.

Some machines have both printing and cutting capabilities. If the machine has both, printing and cutting is one fluid process. If not, you’ll need to move the substrate to the digital cutter once printing is complete.

Cutting

Once the printed material is on the cutting router, it will use information from various sources to precisely cut out your design as requested. It may use laser and optical sensors to detect reference marks, reference dots and the contrast between the light-colored media and the darker printed design. It will also use information from the cutter software — informed by the cut path in the design file — to plot the route along which it will cut out the sign or decal.

The type of cutter and software used will affect the quality of the final product. You need equipment with capabilities such as registration mark sensing as well as software that can communicate with your cutter. The cutting machine must also be correctly calibrated to ensure accuracy. While there will always be a slight margin of error, the device will cut much more precisely when it’s calibrated appropriately. At SpeedPro, we use only the highest quality contour cutting equipment and software and ensure that it’s properly maintained and aligned at all times.

The Benefits of Contour-Cut Signage

Why should you use contour cutting for your signs and decals? The technique has various advantages that make it a smart choice for a variety of project types. Some of its benefits include the following.

Accuracy and Repeatability

Using a cutting machine produces highly accurate results. It enables you to cut precisely along the edges of a design or follow some other cutting path exactly. This accuracy means that you can produce multiple copies of one sign or decal, and they’ll look exactly the same. This consistency is essential to professional-looking graphics.

Fast Turnaround and Efficiency

Contour cutting is an efficient method for producing custom signs. It enables a quick turnaround, which is often crucial for companies in today’s fast-paced business world.

The fact that contour cutting machines can operate largely autonomously helps to speed up the process. The fact that they’re extremely precise helps to reduce the likelihood of having to redo a project. If you’re using a machine that can both print and cut your sign, the process may go even more quickly. Using one device for both printing and cutting eliminates some of the time and labor that’s required when using other methods.

Customization and Unique Design

The most well-recognized benefit of contour cutting is likely customization. The possible shapes for contour-cut signs are practically endless, which allows you to create unique, eye-catching designs. It also enables you to produce signs for a wide variety of purposes using a broad range of materials.

Customizations Available for Contour-Cut Signs

One of the biggest draws of contour cutting is the ability to create unique, custom-shaped signs. Using this method, you can produce signage of nearly any shape, from simple circular logos to an entire company slogan — all cut out precisely to your specifications. The ability to create custom contour-cut signage shapes enables you to make eye-catching signs that will stand out and give you a chance to express the personality of your brand.

The wide range of customization options available means you can use contour-cut signs for a variety of purposes. They’re perfect for:

- Office signage: You can use custom contour-cut business signs to display your company logo, brand slogan or information that employees need to know in the workplace. Using a custom shape will drive home your brand’s personality and help your signage catch people’s attention.

- Store signage: Contour-cut signs are perfect for showing off your store’s logo or creating eye-catching cut-outs of products, celebrities and more.

- School signage: Schools can use contour cutting to create signs and decals of their mascot, label rooms or create other unique decor items.

- Directional signage: Contour-cutting is useful for creating directional signage that’s easy to follow. The customization that this technique enables allows you to give directions in a way that makes the most sense for your situation.

- Special event signage: You can also use contour cutting to produce custom signage and displays for special events such as trade shows, community events, sales, sporting events and more.

- Spot graphics: Using contour cutting, you can cut any shape out of a range of materials, which allows you to place visually appealing graphics on many different surfaces.

- Window decals: Placing decals in windows is an excellent way to get the attention of people walking by your building. Custom shapes enable you to get out your message in more unique and engaging ways.

- Floor decals: Contour cutting also enables you to create decals for use on floors, from logos to slogans to directional items.

- Banners: With contour cutting, you can create uniquely shaped banners for use in your store, at the office or at a special event.

- Acoustic panels: Acoustic panels are used to absorb the excess noise in various spaces, but that doesn’t mean they can’t be a colorful, tasteful addition to your decor. They can be cut and crafted in a vast range of shapes and sizes.

You can make a contour-cut sign a permanent part of your facility or order signs for temporary use. You could, for example, display contour-cut decals in a storefront window to promote a sale event.

When contour cutting prints, you can choose to “cut through” or “kiss cut” your design. These methods differ in the depth at which the machine cuts the material. The cut-through method is the most commonly used. It involves cutting all the way through the medium to create a standalone sign or cut-out.

The other option is to kiss cut the material, a method in which the machine does not pierce all the way through the substrate. You can use this technique to create stickers and decals. To accomplish this, you pierce the material to a depth that cuts out the decal but leaves the backing liner intact. You can then peel the sticker or decal off when you’re ready to use it.

Materials Used for Contour-Cut Signage

Another customizable aspect of contour-cut designs is the ability to use a variety of materials for your signage. The following are some of the materials that work well:

- Acrylic: We can contour-cut acrylic designs if you’re looking for a bold, three-dimensional focus point to use in your office space.

- Coroplast: If you’re hoping to find a cost-efficient product that’s impactful and durable outdoors, coroplast is a great way to go. Once you have them contoured, your graphics can be mounted with the use of H-frames, A-frames and other supports.

- Removable vinyl: Vinyl is easily adaptable, as it can be made in a few different types, printed in several sizes and applied to walls, windows and floors. The types of vinyl available include matte, gloss, calendar, cast, comply, ControlTac, metallic, reflective, fluorescent, iridescent, carbon fiber, diamond plate, etched, frosted, clear and dusted.

- Aluminum: Looking to add visual guidance to your directional signage? Aluminum signs are weather-resistant and can be cut to any shape. Holes can be drilled in the sign for easy hanging. Aluminum signage is great for manufacturing, retail, real estate, parking or directional signage.

- Foamcore: Foamcore is an extremely lightweight material consisting of a polystyrene foam core that’s laminated with a coated-paper stock on both sides. This material is an excellent, affordable choice for temporary indoor applications.

- Rigid plastic: If you need long-lasting signage for either indoor and outdoor use, rigid plastic is an excellent option. Plastic signage is durable yet easy to install and works well for a variety of purposes.

Custom Contour-Cut Signs From SpeedPro

Whatever you’re using your signage for, we can help you achieve your goals. At SpeedPro, we have the tools and expertise to produce custom signage to your exact specifications, and we’ll work with you to determine the right materials and production process for you.

With our top-of-the-line contour cutting technology, we can quickly and affordably produce precisely cut signs and decals. We can print, design and cut nearly any shape on a wide range of materials.

To learn more about how we can help you achieve your visual communication goals, find your local studio to request a free consultation or quote. We have studios across the U.S., and we’d love to be the partner for all of your signage needs. Get started today.